Along with substrates (paper and printable plastics), inks and dry toners are the other main raw materials used in printing. Regardless of printing process or technology, inks and toners both include pigments, a way to carry the pigments to the substrate, and additional chemicals to improve performance. Despite the unfounded “environmental friendliness” claims made by many ink manufacturers and print shops, all inks and toners have real environmental impacts. The key to being environmentally responsible is to minimize these impacts without overstating their significance.

(1) Sheetfed Offset Printing Inks: Offset printing inks are comprised of pigments (colorants), vehicles (oils that carry pigments), and modifiers (chemicals added to impr ove performance). Vehicles are the largest component of ink and are comprised primarily of petroleum products and sometimes some plant-based oils such as linseed (flax). In the late 1980s and early 1990s, certain ink manufacturers began to incorporate soy oil into their ink formulations in an effort to reduce the petroleum content of ink vehicles. The benefits of using plant-based oils rather than petroleum products are many, including that they are made from renewable resources, are lower in volatile organic compounds/VOCs (chemical pollutants emitted into the air), and recycled paper is more easily deinked when printed with plant oil-based ink.

ove performance). Vehicles are the largest component of ink and are comprised primarily of petroleum products and sometimes some plant-based oils such as linseed (flax). In the late 1980s and early 1990s, certain ink manufacturers began to incorporate soy oil into their ink formulations in an effort to reduce the petroleum content of ink vehicles. The benefits of using plant-based oils rather than petroleum products are many, including that they are made from renewable resources, are lower in volatile organic compounds/VOCs (chemical pollutants emitted into the air), and recycled paper is more easily deinked when printed with plant oil-based ink.

After years of experimenting with different ink formulations, many of which performed poorly on press (which I can attest to), ink manufacturers that incorporated plant oils into their ink formulations generally settled on using soy and/or linseed oils to replace a portion of the petroleum in their ink vehicles. In 19 94, the U.S. Congress passed the Vegetable Ink Printing Act, which set plant oil content standards in offset printing inks. In order to qualify as “vegetable-based” or “soy-based”, sheetfed offset inks must contain at least 20% soy and other plant-based oils by formula weight. All my Pantone and process inks meet or exceed the standards set by the Vegetable Ink Printing Act of 1994. Moreover, I only use inks made by companies that publish their ingredient composition list, including pigments, so that the environmental impact of their products can be accurately assessed. Unfortunately, many ink manufacturers do not publish this data, hiding behind “trade secrets”.

94, the U.S. Congress passed the Vegetable Ink Printing Act, which set plant oil content standards in offset printing inks. In order to qualify as “vegetable-based” or “soy-based”, sheetfed offset inks must contain at least 20% soy and other plant-based oils by formula weight. All my Pantone and process inks meet or exceed the standards set by the Vegetable Ink Printing Act of 1994. Moreover, I only use inks made by companies that publish their ingredient composition list, including pigments, so that the environmental impact of their products can be accurately assessed. Unfortunately, many ink manufacturers do not publish this data, hiding behind “trade secrets”.

In addition to incorporating plant-based oils into ink formulations, there are other considerations when assessing the environmental impact of offset printing inks and how print shops respond. First, pigments used in offset inks vary in their toxicity. There has been progress over the last several decades to replace more toxic pigments with less toxic ones. For example, the more toxic cadmium has been replaced with the less toxic diarylide for yellows. However, there remains one pigment in Pantone colors that remains on the California Proposition 65 (Safe Drinking Water and Toxic Enforcement Act of 1986) list of chemicals that are known to cause cancer, birth defects, or other reproductive harm. This is the orange-red pigment used in “Warm Red” ink, a known carcinogen. When customers want a Pantone color that includes Warm Red, I can often substitute another Pantone color that is very close but doesn’t include Warm Red in the mixture. Therefore, I can significantly reduce the amount of Warm Red ink I use and have a lower environmental impact.

Second, there are some specialty inks used in offset print shops that have a greater environmental impact than process and Pantone ink colors. These include metallic inks, fluorescent inks, and oxidizing inks (for printing on plastics). I minimize the use of specialty inks in my shop. I rarely print with metallic inks, but sometimes do because there is nothing else that produces that kind of effect. I do not print with fluorescent inks because the Pantone ink colors are already vibrant. Moreover, I hardly ever print with oxidizing offset inks; when I print on plastic substrates, it is usually on a digital printer with standard CMYK toners.

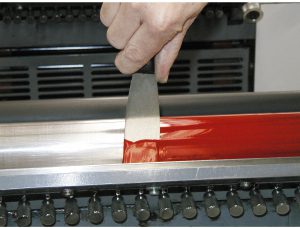

Third, there is the issue of waste ink. Even if a print shop is careful about minimizing waste ink, there is still some used or dried ink that must be disposed of properly. I have been in numerous print shops where press operators just put waste ink onto a sheet of paper, fold it, and throw it in the trash. Waste ink is hazardous and should be disposed of responsibly. I store my waste ink and periodically dispose of it properly at the Alameda County Household Hazardous Waste site in Oakland. I have an account number and paper trail to support this disposal going back to the beginning of Evergreen Printing. I also have a California EPA Identification Number and annually report to the California Department of Toxic Substances Control.

(2) Digital Printing Toners: Like offset printing inks, digital printing toners are also comprised of pigments, vehicles, and modifiers. Instead of oils, toner vehicles are comprised of polyester polymers/resins (fine plastic solids). Toner vehicles are usually petroleum-based although there has been some limited use of plant-based ingredients. The pigments are the same or close to the pigments used in offset inks. There isn’t a significant environmental difference between toners made by different manufacturers of toner-based digital printers.

There is also a proprietary relationship between digital printers and what toner can be used in them. Every manufacturer requires particular toners be used exclusively in their digital printer or the service contract will be cancelled. Thus, print shops have no choice regarding what toner formulations they use. The freedom to choose from many ink manufacturers and formulations in the offset printing world simply does not exist in digital printing.

Regarding disposal of waste toner and consumables, all digital printer manufacturers allow print shops to mail waste toner and used consumables back to manufacturers for recycling or proper disposal. However, they don’t make it easy. In practice, it becomes the print shop’s responsibility to determine how to return waste toner and used consumables to the manufacturer. I periodically return all my waste toner and used consumables back to Canon and Xerox.